Introduction

Not long ago, engineering design meant a lot of trial, error, and gut instinct. Now, things are moving at a completely different pace. Driven by new algorithms, powerful simulation tools, and artificial intelligence, today’s engineers are no longer limited by traditional processes or intuition alone. Manufacturers are now utilizing advanced digital tools to develop products that are not only stronger and lighter but also more efficient. This innovative approach expands the limits of what can be achieved in various sectors, including aerospace and electric vehicle production.

ToffeeX is one of the most exciting players in this new era. In a recent podcast we featured Thomas Rees, a key member of the ToffeeX team, leading partnership building and research direction. The conversation offered an in-depth look at ToffeeX, exploring its distinctive attributes, technological foundations, and swift ascent as an indispensable asset for pioneering engineering teams.

Generative Design & Topology Optimization: What’s the Difference?

Modern design innovation frequently revolves around two key concepts: generative design and topology optimization.

- Generative Design is a design philosophy where algorithms automatically generate a wide range of potential solutions based on user-defined goals and constraints. Think of it as mimicking nature’s evolutionary process: creating, testing, and refining designs until the best candidates emerge.

- Topology Optimization is a mathematical technique that finds the optimal material layout within a given space, subject to performance targets and physical constraints. For example, in thermofluid applications, it helps engineers design structures that maximize cooling or minimize pressure drop.

At ToffeeX, these concepts come together through advanced algorithms built atop robust computational fluid dynamics (CFD) simulations, allowing engineers to explore, test, and optimize designs more effectively than ever.

Solving Real Thermofluid Challenges Across Industries

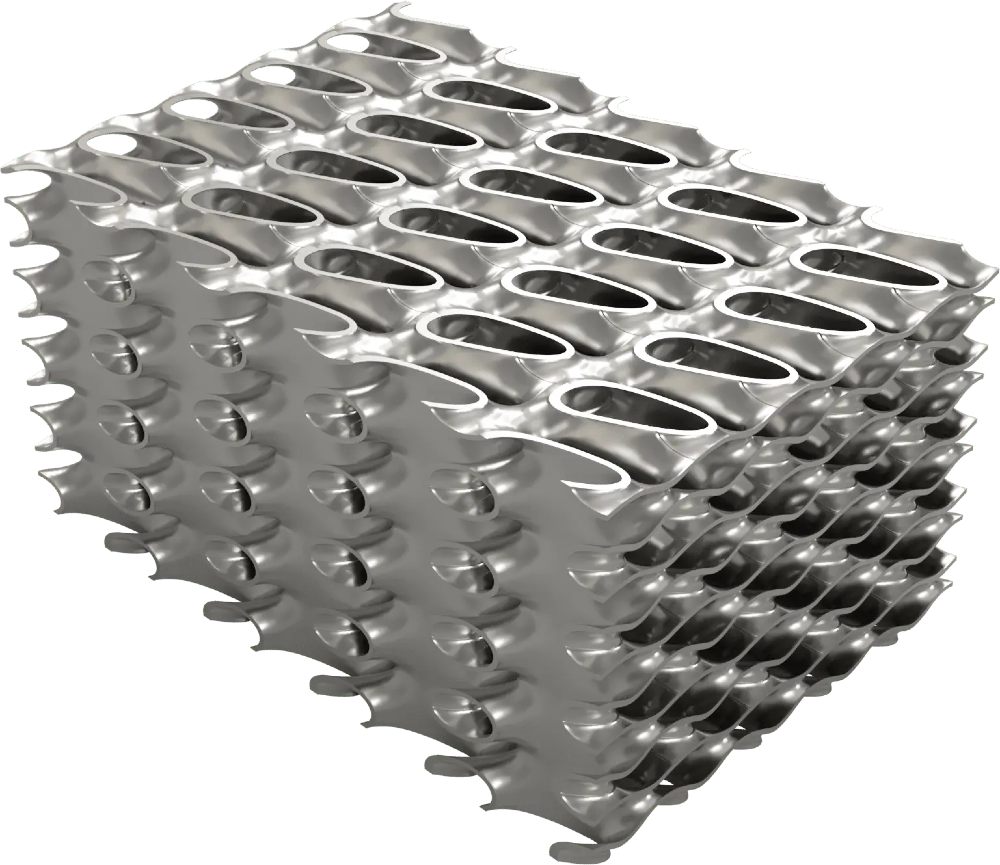

While heat sinks are a classic example, the applications of ToffeeX extend far beyond. The platform is already being used in real-world thermofluid applications such as:

Cooling Plates: Used to manage heat in sensitive electronics, ToffeeX enables engineers to optimize cooling plate designs for power modules and large-scale battery packs in electric vehicles. This helps improve energy efficiency, prolong component span, and ensure safe operation even under demanding conditions.

- Heat Exchangers: ToffeeX streamlines the design of advanced heat exchangers, such as air-to-oil, fuel-to-oil, and liquid-to-liquid types that are vital for temperature regulation in power plants, industrial machinery, and aerospace systems. The platform’s optimization capabilities lead to more compact, efficient, and cost-effective exchanger designs.

- Manifolds: From distributing fuel and air in engines to managing exhaust flows, manifolds play a critical role in automotive and aerospace performance. ToffeeX helps engineers create manifold geometries that minimize pressure loss and ensure even flow distribution, supporting both performance and emissions goals.

- Manufacturing: In high-pressure die casting and similar manufacturing processes, ToffeeX is used to optimize injection runner systems. This leads to better material flow, reduced defects, and improved quality in complex metal components, boosting production efficiency and lowering waste.

Any engineering challenge involving internal fluid flow or thermal management can benefit from the speed, flexibility, and optimization power of ToffeeX.

Speed, Precision, and Seamless Integration - Toffeex’s Approach

What sets ToffeeX apart in the crowded field of engineering software is focus and speed.

Unlike platforms that try to cover every possible use case, ToffeeX is laser-focused on thermofluids and topology optimization. Every feature is built around this core, ensuring the best possible results for these complex challenges.

Engineers can import their geometry, set up their simulation and optimization problems (boundary conditions, materials, and constraints), and then run rapid design iterations. Whether optimizing for additive manufacturing, weight, performance, or cost, ToffeeX makes it easy to generate and compare hundreds of designs in minutes, not days.

Integration is straightforward: ToffeeX supports standard CAD and simulation file formats, so it fits naturally into your existing workflows. This simplicity means engineers and teams can quickly adopt and benefit from its capabilities, without painful software onboarding.

Adapting to Modern Engineering Workflows

Introducing new tools into established engineering processes is always challenging, especially when different teams, from CFD experts to manufacturing engineers, need to collaborate. ToffeeX addresses this by providing a layered interface: generalists get a streamlined, intuitive workflow, while experts can dig into advanced options as needed.

Moreover, ToffeeX prioritizes user-driven workflows and high-quality data handling (import/export), freeing engineering teams to concentrate on problem-solving rather than software complexities.

AI Agents and the Next Wave of Design

AI is starting to play a bigger role in how engineers work, not just automating simulations, but helping to create and refine designs on the fly. The team at ToffeeX is already exploring how AI agents could take on more of the heavy lifting, letting engineers focus on the bigger picture. As design workflows become more intelligent and autonomous, ToffeeX aims to give engineers the tools they need to stay ahead of the curve.

Conclusion

From aerospace components to electric vehicles and beyond, engineering teams face growing pressure to innovate, optimize, and deliver results at unprecedented speed. Combining generative design, topology optimization, and high-performance simulation in a single focused platform, ToffeeX empowers engineers, managers, and innovators to unlock new possibilities while staying ahead in a rapidly evolving world.

Ready to take your designs to the next level? Contact the ToffeeX team for a demo, or try it today.